Video

Introduction

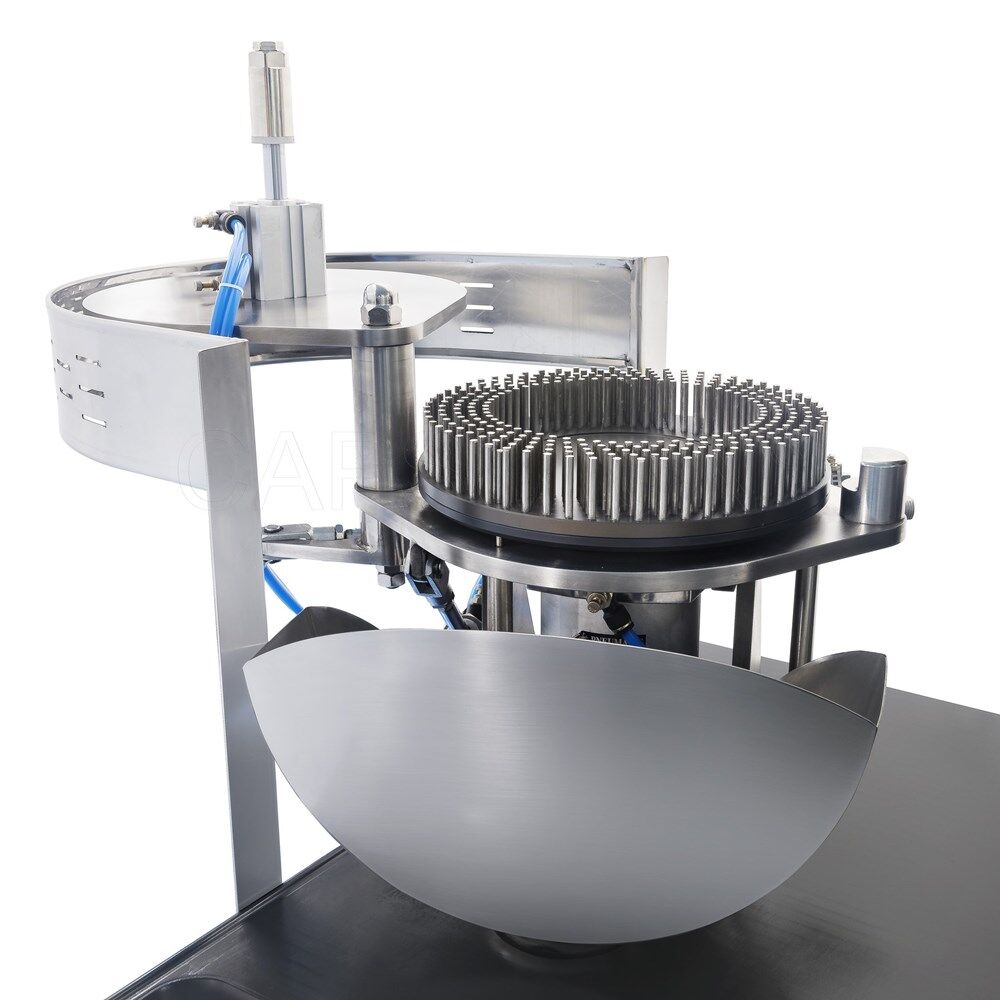

After CapsulCN accumulated production experiences in manufacturing several thousand sets of JTJ-V Capsule Filling machine, CapsulCN developed the latest JTJ-V Pro+ can operate more efficiently and smoothly.

Numerous innovative operational and safety features that streamline the production process and provide processing speeds of up to 50,000 capsules per hour.

The capsule filler can handle all capsule sizes from 000 to 5. A special design allows for changing mold for different size capsules within 15 minutes easily, simply, and precisely.

Can fill material in powder, pellet, or granule forms.Tested by CapsulCN laboratory, failure-free in 10,000 hours of operation.

Specifications

| Model | JTJ-V Pro+ |

|---|---|

| Control Panel | Siemens |

| Capsule Size | 000#, 00L#, 00#, 0L#, 0#, 1#, 2#, 3# |

| Capacity | 30,000 to 50,000 per hour |

| Electrical Supply | As electrical facilities vary from country to country, please provide your specifications at time of order so that the correct motors are supplied with your machine |

| Vacuum Pump | 40m3/h |

| Compressed Air | 0.03m³/min,0.7MPa |

| Overall Dimensions | Length: 1140mm Width: 700mm Height: 1630mm Weight: 380kg |

| Package Size | Length: 1650mm Width: 800mm Height: 1750mm Weight: 500kg |

Remarks

- Double loading system, up to 50,000 pcs / hour, close to the output of a fully automatic filling machine NJP-800.

- All capsule trays are hard anodized and the service life is extended by 4 years.

- It has an infinite variable speed of filling table with independent power and fixed point filling that results in accurate dosage.

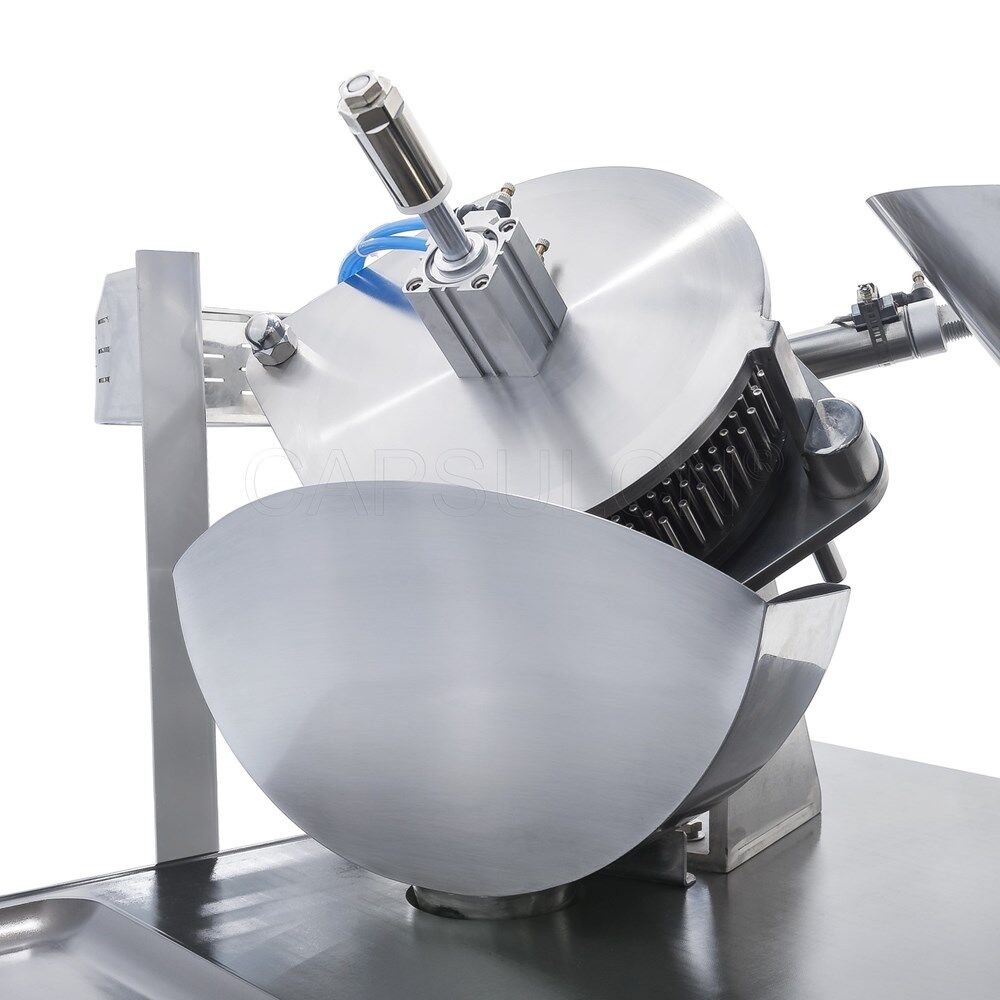

- The horizontal closing system is more efficient, safety, and smoothly closes without damaging the capsules;

- An independent motor box from the german brand BECKER, improving the durability and quality of the system

.jpg)

review(s)

Perfect

High production efficiency, with more than 1 year is very perfect.

Sean

|

2/27/2021 1:08 AM

Was this review helpful?

(0/0)