Cellulose is a natural polymer compound whose chemical structure is a polysaccharide macromolecule taking anhydrous β-glucose as the main component. A series of cellulose derivatives can be obtained by chemical modification, and Cellulose Ether is one of them. Cellulose Ether is obtained by reacting cellulose with NaOH, etherification reaction with various functional monomers such as methyl chloride, ethylene oxide, propylene oxide, etc. removing the by-product salt and cellulose sodium by water-washing, and other further processes. Cellulose Ether is an important derivative of cellulose, which can be widely used in medical and health, household chemicals, paper, food, medicine, construction, materials, and other industries.

In the medical field, these substances are more widely used: Methyl cellulose, Ethyl cellulose, Hydroxypropyl methyl cellulose, Hydroxypropyl cellulose, and cellulose microciystalline. The below is the brief introduction about them.

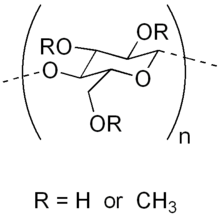

Methyl cellulose MC

In the pharmaceutical industry, Methyl cellulose of low or medium viscosity can be used as a binder or coating for tablets, and Methyl cellulose of high viscosity can be used as a backbone material for sustained release formulations. Methyl cellulose of high degree of substitution, low viscosity can be used for aqueous coating, as well as suspending agent, thickener, emulsion stabilizer, protective colloid. Methyl cellulose of high degree of substitution and high viscosity can be used as eye dropping, and a matrix material for creams or gels.

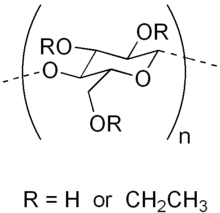

Ethyl cellulose EC

Ethyl cellulose is insoluble in water, but soluble in organic solvents, such as ethanol. A good filming property enable the Ethyl cellulose to be used as a film coating for water-sensitive medication, and with the increase of viscosity, the Ethyl cellulose film will be stronger and more durable. Being combined with a water-soluble polymer, Ethyl cellulose can adjust the diffusion rate of the medication of the film-coated layer, being used as a sustained-release coating layer. The ultra-fine grade of Ethyl cellulose can be used as a skeleton material of the sustained release preparation of direct tablet pressing. In addition, Ethyl cellulose can be used as a binder in the ethanol wet granulation, especially for granulation and tableting of water-sensitive drugs. It can also be used as a thickener for creams, lotions, and gels.

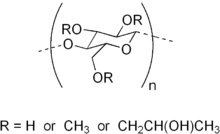

Hydroxypropyl methyl cellulose HPMC

Hydroxypropyl methyl cellulose is a multifunctional pharmaceutical excipient that can act as a thickener, dispersant, emulsifier and film former. As a film coating or a binder in an oral solid preparation, Hydroxypropyl methyl cellulose can greatly improve the stability and dissolution of the medication, and enhance the water repellency of the tablet, and it is one of the raw materials for producing vegetarian capsule. It can also be used as a suspending agent for suspensions, matrix material for ophthalmic preparations, and skeleton material for hydrophilic gel skeleton sustained-release tablets and intragastric floating tablets.

Low degree of substitution Hydroxypropyl cellulose L-HPC

L-HPC is mainly used as a tablet disintegrating agent and a binder. As the disintegrating agent and a binder L-HPC is widely applied, especially for tablets that are not easily formed, plastic and brittle, and with L-HPC, tablets can be easily pressed and formed. L-HPC could also be used to improve the hardness and the brightness of the tablet. make the tablet disintegrate quickly to improve the intrinsic quality and efficacy of the tablet.

Cellulose microciystalline

There are hydrogen bonds between the molecules of cellulose microciystalline, which will be associated under pressure, so it has high compressibility and is often used as a binder. When the compressed tablet encounters fluid, the moisture quickly enters the tablet, hydrogen bonds of cellulose microciystalline break immediately, hence, cellulose microciystalline also can be used as disintegrating agent. In addition, cellulose microciystalline can be used as a diluent because of its lower density, larger specific volume, and wider particle size distribution.