For capsule coating, the content is depended on the area and thickness of the coating, and different coating solution is suitable for each different product.

- Dipping processes are suitable for small-scale usage. After the formulation is completed, use some equipment to make the capsule spin in the solution until the coating is as thick as required.

- Horizontal drums use a circular drum, and spraying device sprays the solution evenly over the surface of the capsule by drying the air.

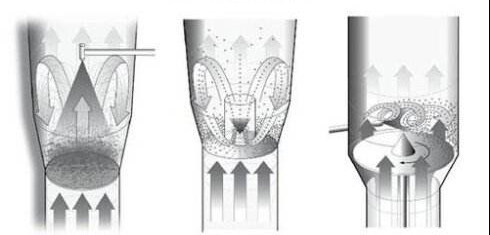

- Fluidized air bed processes keep the capsules fluid by continuously vented air, and set spray points at the proper position to spray the solution onto the capsule surface.

In addition, some companies introduced new coating machinery, which combines the above methods, and it is still in development.

In the coating process, the finished product may not be satisfactory due to materials, environment, etc., and followings are common problems:

The properties of the coating materials may change owing to temperature, pH, etc., so many immediate aqueous materials should be processed as soon as possible or cooled.

Because of the properties of the gelatin, capsules may become soft or sticky during coating, or the capsule may become brittle after long-term storage, therefor precoating is required.

The coated capsule surface may not be completely well coated, and caused a rugged surface resembling an orange texture, it is called orange peel effect. This problem can be solved by increasing the content of the plasticizer or by using a double-layer coating method.

If the medication is cracked during the process, it is necessary to increase the content of the plasticizer or adjust the formulation.

The solution may go into the capsule through the gap between the capsule cap and capsule body. For this situation, add some Aerosil 200 into the formulation to quickly fill the middle space. Adding a plasticizer and updating the device can also help to solve the problem.

Furthermore, the physical properties and the appearance of the coating can be improved by an overcoat.

It should be noted that the production of any pharmaceutical excipients should be sufficient theoretically safe and a large number of practical tests are required. This article only gives a general overview of the coating, and for specific issues should go to the industry experts.